Tanning is the process of treating skins and hides of animals to produce leather.

Properly made and sourced leather is a truly sustainable material. Hides and skins are mostly a by-product that is dependent on the meat and dairy industry. Transformation into leather is the best use for those hides. Leather makes a sustainable contribution to a society that needs to consume less, reuse more and a recycle everything.

It involves a process which permanently alters the protein structure of skin, making it more durable and less susceptible to decomposition, and where necessary colouring it. Before tanning, the skins are dehaired, degreased, desalted, and soaked in water over a period of six hours to two days.

Traditionally, tanning used tannin, an acidic chemical compound from which the tanning process draws its name, derived from the bark of trees. Vegetable tanning is the oldest tanning method, it uses extracts from wood, and nuts of trees and shrubs with responsible suppliers ensuring these are from a sustainable source. It usually takes longer to tan leather using this method, but the result is a leather with distinctive aesthetic and handle that ages beautifully.

An alternative method, developed in the 1800’s, is Chrome Tanning, and Chromium Salts are used instead of natural tannins.

The process of chrome tanning is constantly being upgraded by better uptake, less usage, comprehensive recycling, reduced water consumption and careful management of waste. Best practices of chrome tanning use half the chemicals required by other methods and produces effluent content below legal requirements. Chrome tanning produces consistent leathers that can be used or worn year after year without any loss of properties.

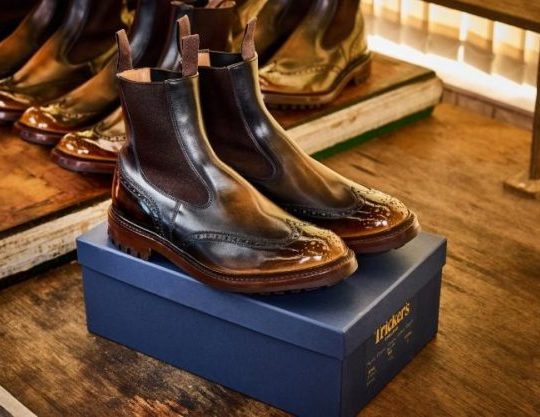

Tricker’s Olivvia leather uses an all-natural tanning procedure. In this process, an essence from olive leaves is used for tanning. The olive leaves provide a completely chrome-free tanning alternative and are a bi-product of the olive industry, diverted from being burnt as a waste product, thereby avoiding the environmental impact of that process. This chemical-free leather combines the natural smell of leather with the warm undertone of olives.

One of the newest leathers in the market place, Tricker’s is honoured to be the only shoemaker in the world using Olivvia leather. Not only that, but we have also secured an exclusive deal enabling us use of this innovative leather within the footwear market.

All tanning methods are well managed in production and when all the variables are considered, there is little difference between them regarding the environmental impact.