In the making department, a wooden shank is added to the sole, providing support to the shoe. A layer of cork then fills the cavity created between welt and insole, providing flexibility and insulation, and moulding itself to the shape of the foot during wear, enhancing comfort and fit of the shoe. Leather midsoles are placed over the cork filling and secured in place.

The midsole can be glued then stitched or glued with the sole and then stitched onto the welt as one. If the sole is rubber such as the Vibram micro sole, these can’t be stitched. Instead, we glue the sole to the midsole and then stitch the midsole to the welt. When it’s possible to stitch the sole, like on our more common soles, Dainite Studded, Leather, Ridgeway, the midsole is only glued and then the sole stitch will go through the sole, midsole and then the welt.

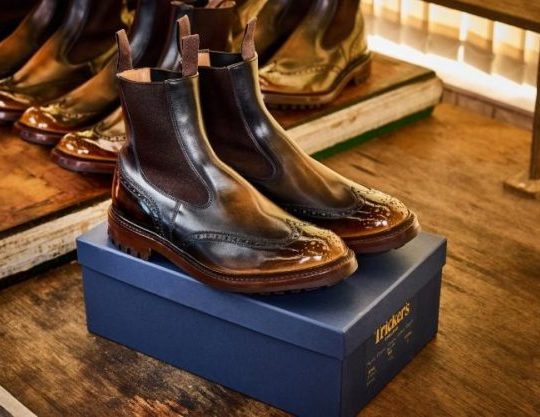

Tricker’s uses a number of different leather and rubber out-soles depending on the use of the shoe and will build up the sole and heel in layers.

The excess of the sole is then rounded off and lock stitched to the welt. The soles are then allowed to dry naturally for a number of days before the heels are built and nailed in place, completing the making of the shoe, ready for finishing.